The needs of today's market, together with the expertise gained in over 80 years of excellence in the manufacture of gear pumps, have led us to produce our Type AL gear pumps series. Being made fully from AISI 316 stainless steel and other carefully selected materials makes them especially suitable for use in the food, chemical and pharmaceutical industries, and in all applications requiring a first-class pump for difficult fluids.

The AL Series is the culmination of our gear pump manufacturing, producing a series of pumps that meet the standards and requirements demanded by today's market.

Stainless steel gear pumps are characterised by the following:

- The materials involved comply with FDA requirements for food use.

- Mechanical seal or packing seal.

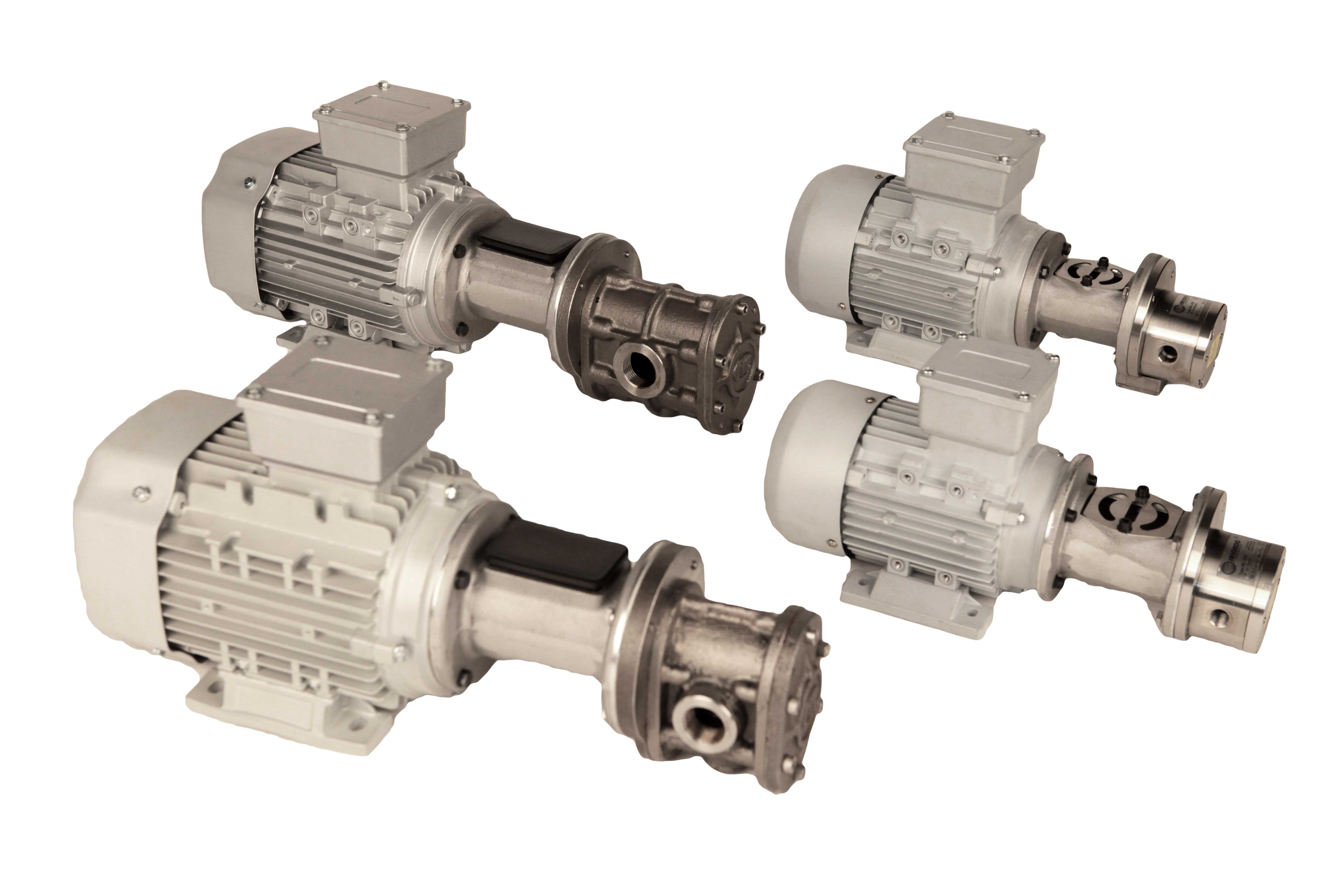

- The AL-0 and AL-1 models are manufactured in a B14 flange version without feet, and can be coupled to an 8-, 6- or 4- pole motor with an aluminium flange. They can also be mounted on a base plate with a bracket.

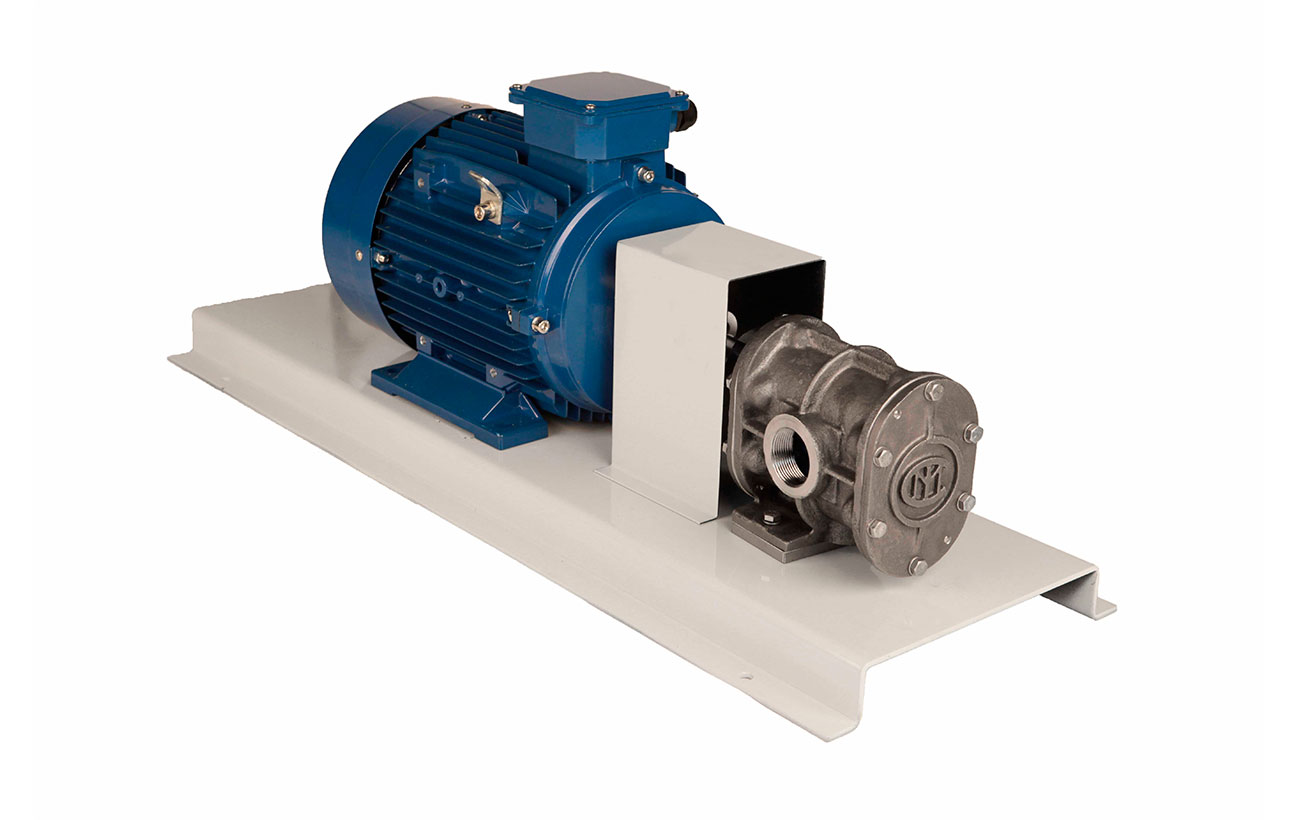

- AL-3 and AL-4 pumps are only manufactured in foot-mounted version, and can be supplied mounted on a base plate and elastically coupled to a motor or geared motor, with a transmission pulley to another shaft, or with a universal joint.

- Watertight seal between body and covers using O-ring.

- Gas threaded connections in standard format. As an option, it can be supplied with DIN 32676 sanitary fitting.

- Rolling on high performance self-lubricating polymer bearings.

- Suitable for working in both directions.

- An external safety valve can be installed as an option.

- Type-approvable according to ATEX Standard.

- Straightforward operation, service and maintenance.

- In the food industry, transferring oils, dairy products, chocolate, tomatoes, water, juices, etc.

- In the chemical, pharmaceutical, medical technology and environment industry, for the transfer of aggressive and corrosive liquids, as well as fluids with poor lubricating properties. Fluids must be clean, without abrasive particles and/or suspended solids, and may require prior filtering.

- Suitable for precision dosing.

- Fluids with viscosity between 1 and 8000 mPas. The pump can be adapted to a wide range of speeds, in accordance with the viscosity of the liquid to be transferred.

- Maximum working temperature 180 ºC.

- Normal working pressure level up to 10 bar.