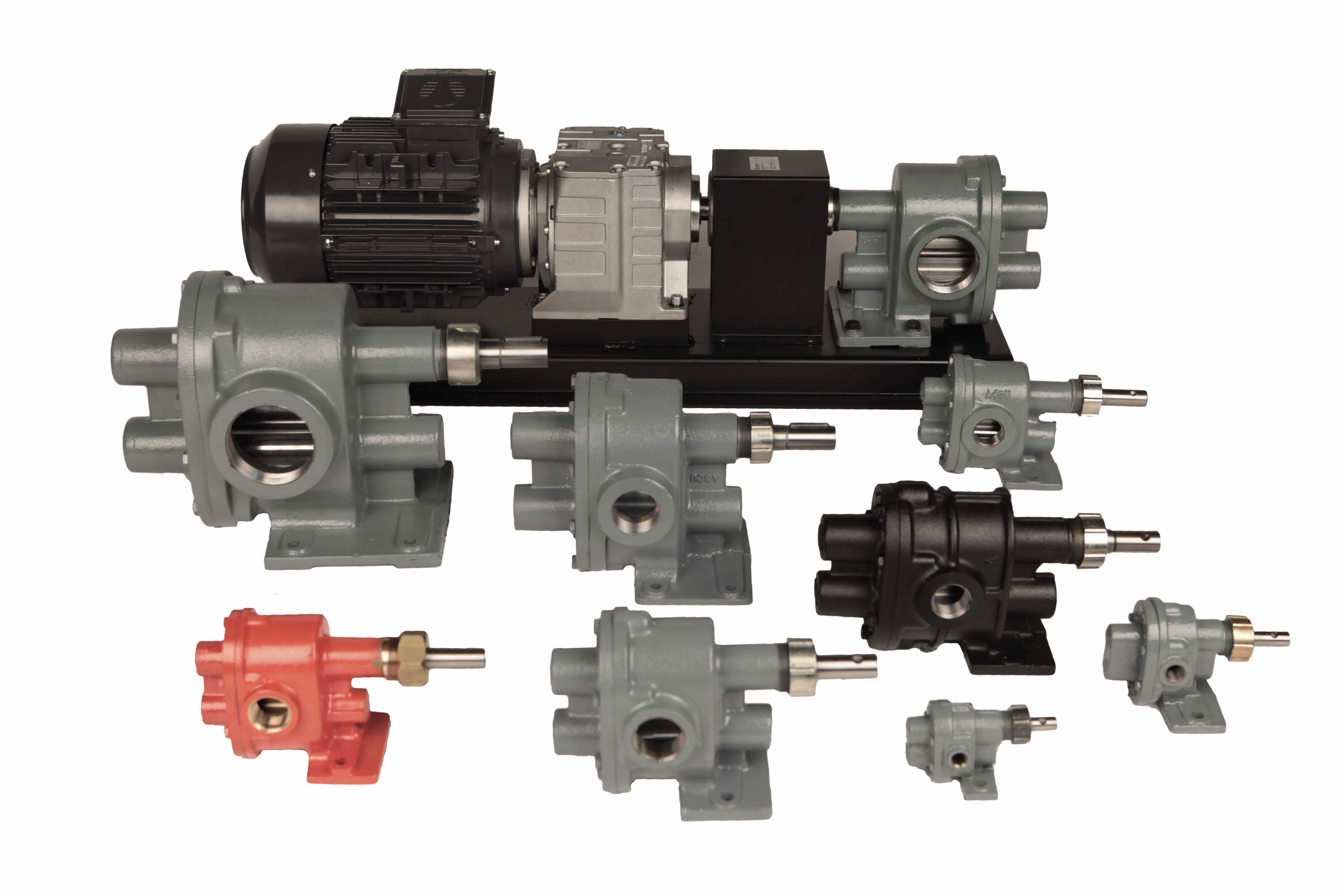

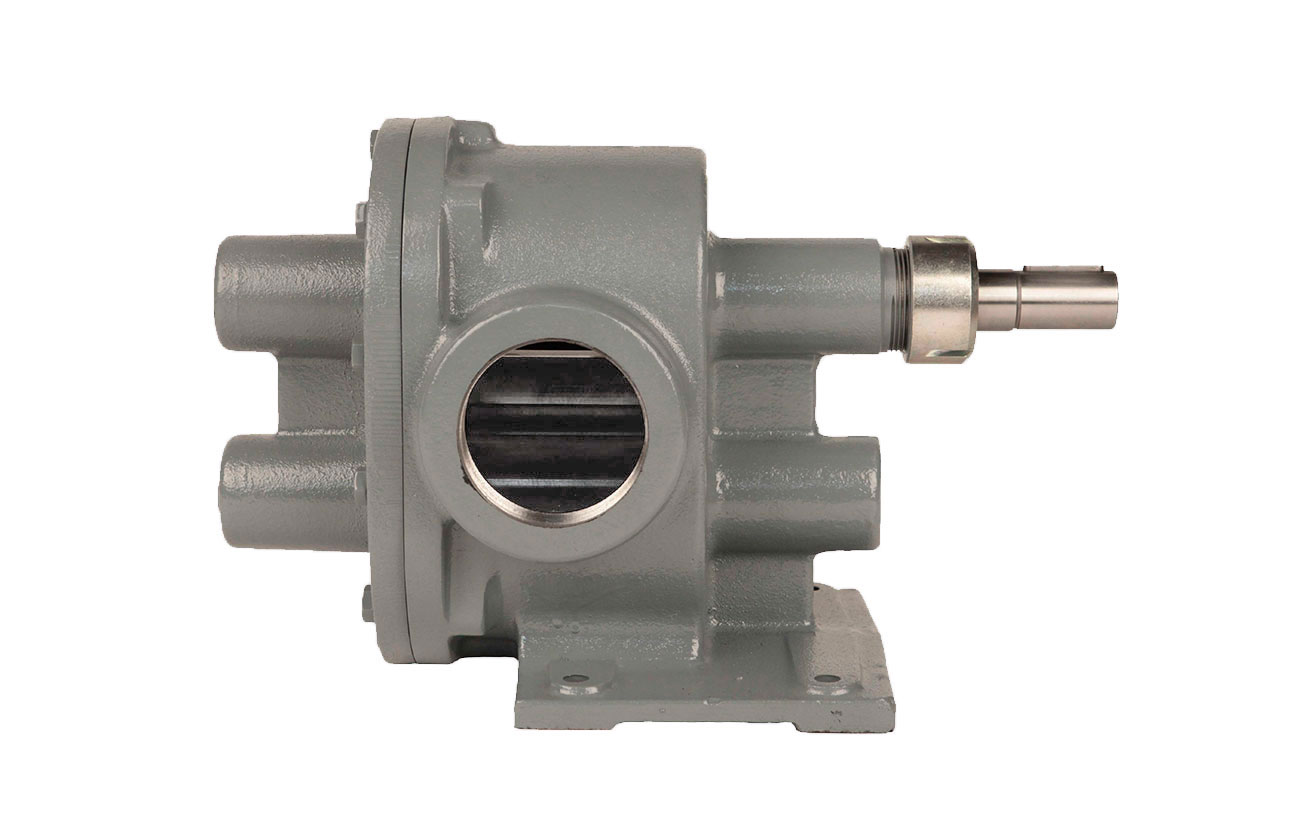

Type A gear pumps are compact assemblies consisting of a cast body that houses a set of rotary gears, and two connecting ports. When the drive shaft is operated, the pump sucks in through one port and discharges the liquid out through the other, with the resulting pressure and flow rates being directly proportional to the power and speed applied, respectively.

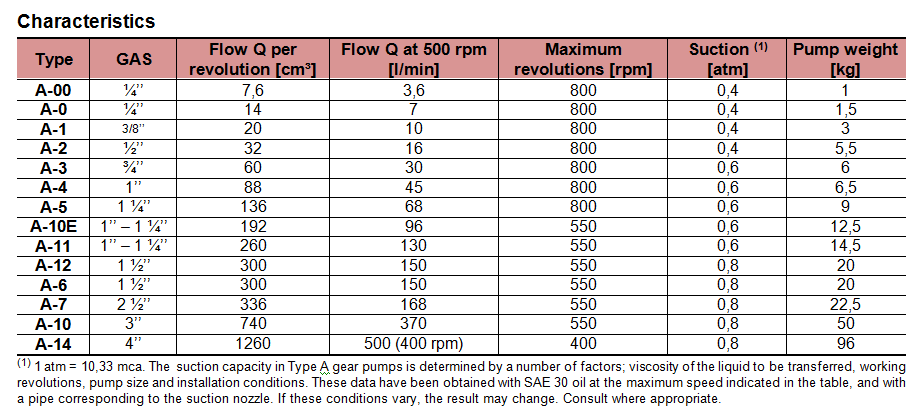

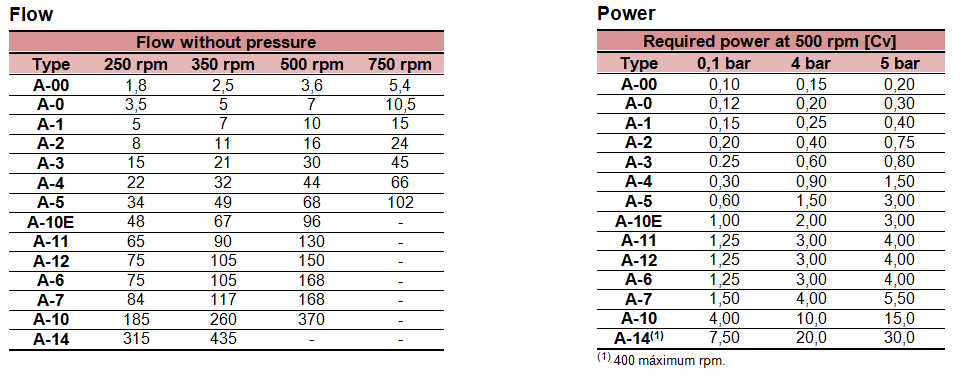

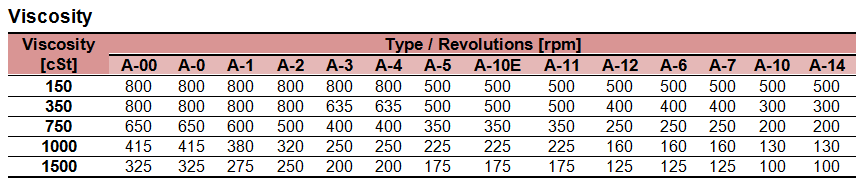

Speed in this type of pump should be between 100 and 750 rpm, thus ensuring a long working life with minimum care in this application range. Remember that the output flow in gear pumps is directly proportional to the number of revolutions.

The Type A model can work in both directions, although use in gland nut tightening direction is recommended. This type of pump is manufactured as standard with a right-hand thread, and in many cases also with a left-hand thread for use with a universal joint drive. If the pump must work in both directions, it can be manufactured with a locknut or a setscrew on request.

The noise level for Type A pumps ranges from 72 dB to 80 dB in larger models. These Type A pump models allow the transfer of liquids with a maximum viscosity between 1° and 250° E (1-1900 cSt).

The maximum temperature of the liquid to be transferred is 225°C, although a higher temperature range is possible with suitable packing.

The maximum working pressure in operation with a liquid of viscosity 1° E (H²O) is 8 kp/cm², while with liquids of viscosity 25° E, like many oils, it is 14 Kp/cm². See the Type F pump range if a higher speed range and/or operating pressure range is required.

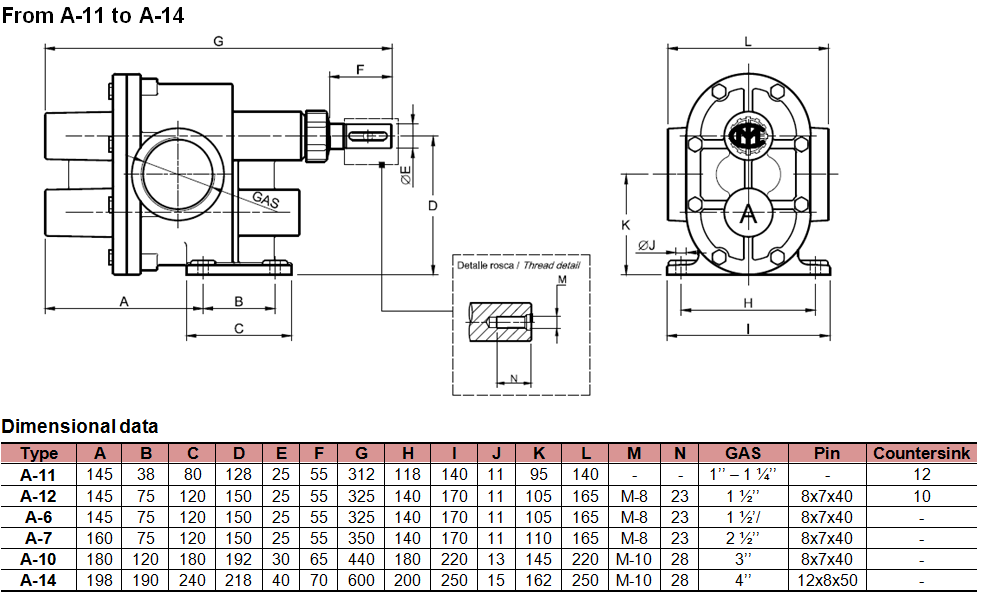

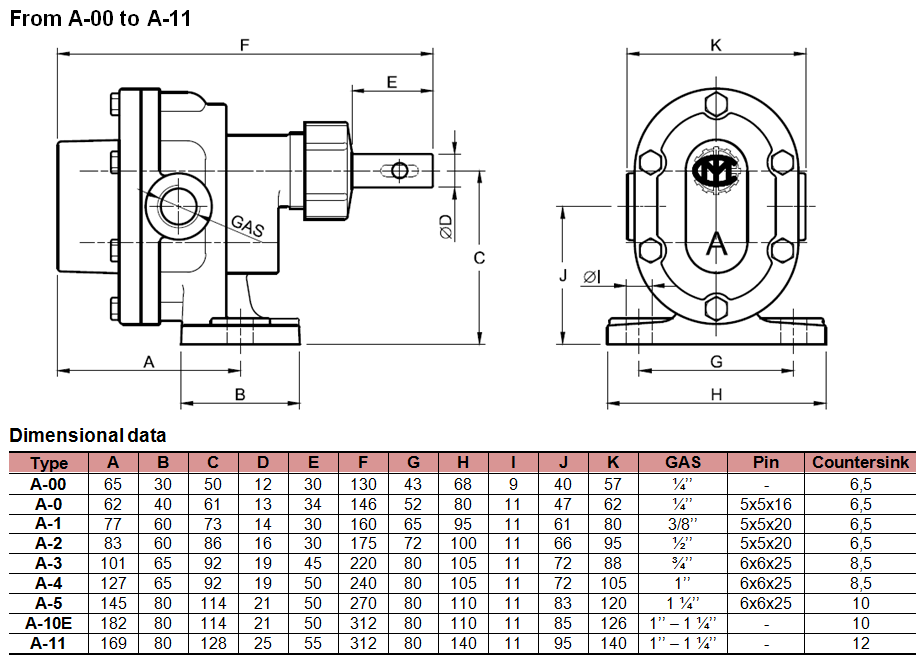

Type A gear pumps are manufactured in a range covering 13 different sizes, to attempt all flow rate requirements between 1 and 450 l/min. 8 of these 13 sizes are available in three different materials, in order to cover different types of liquids:

- Iron. Cast-iron body, carbon steel gears and hardened steel shafts, and used with lubricated, non-corrosive liquids.

- Iron and stainless steel. Cast-iron body, AISI431 stainless steel gears and AISI 420 tempered stainless steel shafts.

- Bronze. Bronze body and gears and AISI 304 stainless steel shafts.

- ATEX. The standard versions of A-6, A-7, A-10 and A-14 have bronze bearings and an O-ring seal, as well as the option of using a mechanical seal, thus ensuring compatibility in an ATEX zone.

The A-10E, A-11E and A-12 models are manufactured with PTFE graphite bearings with thread for left-hand glands, making them particularly suitable for direct coupling to the tractor's output shaft with a universal joint. The A-5 model is also manufactured in this version as an option. Other models can also be supplied with a left-hand threaded plug; please enquire if required.

On request, these models can be manufactured in different versions with special, tempered and treated materials, thus allowing work with special liquids, corrosives, high temperatures, excessive pressures, etc.

Suitable for multiple applications, especially where low speeds are required, for example:

- Lifting and transfer of various medium and high viscosity liquids (paints and varnishes, syrups, soaps and cosmetics, asphalts, diluted glycerines, dyes and disinfectants, alcohol inks, etc.).

- Fumigation services in agricultural tasks.

- Coolant circulation in marine and stationary motors.

- Greasing and cooling services in machine tools.

- Various industrial applications.